As a company serving the hygiene and wet wipes industry, we understand that buyers often look beyond appearance or basic specifications when selecting a supplier. For a professional wet wipes machine manufacturer, certifications play a practical role in validating manufacturing discipline, system management, and long-term equipment reliability. At ZLINK, we view certification standards as part of daily operations rather than promotional labels, because they influence how our equipment performs throughout its service life and how our wet wipe solution is delivered to customers worldwide.

Certifications as a Foundation for Manufacturing Consistency

In wet wipes equipment manufacturing, consistency matters more than short-term output. Certification systems such as CE compliance and ISO management standards provide a structured framework that governs design, assembly, testing, and documentation. These systems help ensure that each wet wipes machine manufacturer follows repeatable processes rather than relying on individual experience alone. From material selection to electrical safety and mechanical integration, certified workflows reduce ambiguity and support stable machine performance across different production environments. For buyers in the wet wipes industry, this consistency directly affects installation efficiency, operator training, and daily production stability.

How Certifications Connect to a Practical Wet Wipe Solution

Certifications are not isolated documents; they influence how a complete wet wipe solution is built and delivered. Our approach focuses on integrating certified equipment design with application-oriented engineering. This is especially relevant for wet wipes factories and brand owners who require hygienic production conditions and predictable output quality. By aligning equipment development with recognized standards, we are able to support automation, process hygiene, and equipment durability in a structured manner. Over a typical service cycle of up to ten years, standardized manufacturing practices help maintain operational reliability and simplify maintenance planning.

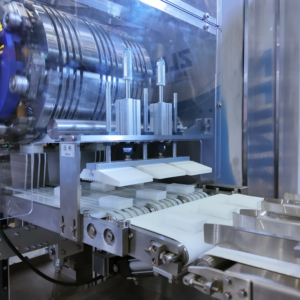

Equipment Design Illustrated Through the WE-SF2 SUPERMINI Line

One example of how certified processes translate into practical equipment is the WE-SF2 SUPERMINI 3D PACKING WIPES PRODUCTION LINE. This portable wet wipes production equipment is designed to support compact layouts while maintaining sanitary production conditions. Compared with traditional semi-automatic lines, the system enables higher operating speed and improved product handling, while preserving a natural appearance and three-dimensional packaging form. Such design outcomes are not accidental; they reflect controlled manufacturing processes and verified safety considerations that align with certification requirements, supporting efficient deployment in diverse production settings.

Conclusion

Certifications validate a wet wipes machine manufacturer by reinforcing structured manufacturing, verified safety, and consistent engineering practices rather than symbolic recognition. For customers seeking a dependable wet wipe solution, certified systems provide confidence in equipment lifespan, process stability, and long-term service alignment. At our company, certification standards support how we design, manufacture, and deliver equipment that fits real production needs in the wet wipes and hygiene industries.