The demand for disinfectant wipes has surged in recent years, pushing manufacturers to identify the most effective machinery for production. Selecting the right wet tissue machine is crucial, particularly in the context of meeting stringent hygiene standards while ensuring efficient output. Businesses need to understand what features to look for in a customized wet wipes manufacturing machine to ensure optimal production of disinfectant wipes.

The Advantages of the WE-SF2 Supermini Production Line

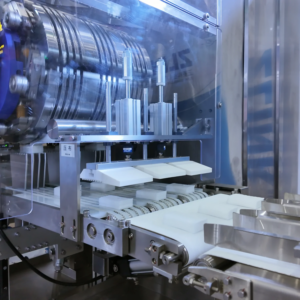

Among the various options available in the market, the WE-SF2 Supermini 3D Packing Wipes Production Line stands out as an ideal wet tissue machine for disinfectant wipes. This portable equipment boasts a stylish design that enhances the aesthetic appeal of the finished products while maintaining a robust three-dimensional form. Unlike traditional semi-automatic production lines, the WE-SF2 offers superior sanitation, faster production speeds, and a more natural appearance for the wipes, making it an excellent alternative to outdated production methods.

The hygiene features of the WE-SF2 are particularly noteworthy. Its design includes a conveyor belt that is easy to disassemble and clean, facilitating regular sanitation and compliance with safety standards. This ease of maintenance ensures that manufacturers can uphold the highest levels of hygiene, which is especially critical for products intended for disinfecting surfaces.

Innovative Features for Enhanced Hygiene

When producing disinfectant wipes, it’s essential to consider machinery that offers innovative hygiene solutions. The WE-SF2 incorporates pipeline disinfection capabilities with a hygiene-grade low point drain-out design. This feature ensures that there is no residue or dead corners where contaminants could accumulate. The 3D design standard employed in the machine allows for easy pasteurization or Clean In Place (CIP) processes, ensuring that the entire production line remains sterile. Such features are vital for manufacturers who prioritize the cleanliness of their products and operations.

Customization for Production Needs

Another significant benefit of the WE-SF2 wet tissue machine is its adaptability to various production requirements. As a customized wet wipes manufacturing machine, it can be tailored to meet the specific needs of different businesses, whether they are focusing on large-scale production or smaller batches. This flexibility allows manufacturers to efficiently respond to market demands and consumer preferences without sacrificing quality.

Partnering with ZLINK for Your Production Needs

In the expanding market for disinfectant wipes, selecting the right wet tissue machine can set your business apart. We at ZLINK are committed to providing high-quality, customized wet wipes manufacturing machines that cater to diverse production needs. Our WE-SF2 Supermini production line combines innovation and hygiene to enhance your production efficiency and product quality. We invite you to explore how our solutions can elevate your disinfectant wipe production, ensuring that you meet both industry standards and consumer expectations. Let’s work together to achieve your manufacturing goals with confidence and excellence.