- NO.5 Boao Technopark, Jian She Nan Road

- marketing@zlink2012.com

- +86-371-60192168

The RLA series automatic lid applicator machine combines advanced industrial robotics with machine vision technology for unparalleled speed and precision. Designed with a high-speed robotic arm, it performs rapid pick-and-place cycles with exceptional agility.

Key Features:

With our lid applicator machine, your production line achieves maximum efficiency, precision, and reliability while minimizing manual intervention.

The ZLINK RLA series robotic vision lid applicator machine is engineered for high-speed, precise, and fully automated lid application in wet wipe production. Combining advanced robotics with machine vision, it ensures accurate lid-picking, gluing, and attachment while seamlessly integrating with various packaging lines. This versatile capping solution significantly boosts production efficiency, reduces manual labor, and maintains consistent product quality across different wet wipe packaging formats.

| RLA-070/120 LID APPLICATOR | ||

| 【Technical Data】 | ||

| Device Model | RLA- 070 | RLA- 120 |

| Robot Model | HRP-560 | HRP-560( 2sets) |

| Capping accuracy | ±1mm | ±1mm |

| Labeling accuracy | ±1mm | ±1mm |

| Wet wipes height | H20~ 110mm | H20 ~110mm |

| Cap size | L50~130mm W50~90mm H4~10mm | L50 ~130mm W50~90mm H4 ~10mm |

| Label size | L30 ~ 100mm W30 ~80mm | L30 ~100mm W30~80mm |

| Number of labeling machines | 2(Automatic switching) | 2(Automatic switching) |

| Capping speed | 70 bag /min (Speed is related to cap type) | Regular lid 120 packs/min Special-shaped lid 90 packs/min |

| Equipment size | L3100mm W1300mm H2000mm | L4220mm W1500mm H2000mm |

| Power supply | AC380V50/60HZ Three-phase five-wire system Capacity 3kVA | AC380V50/60HZ Three-phase five-wire system Capacity 5kVA |

| Air source | 0.6~0.8MPa 30L/min | 0.6 ~0.8MPa 70L/min |

| Equipment weight | 1500Kg | 2000Kg |

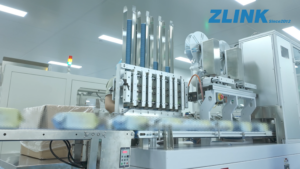

Photos of ZLINK RLA Series

Explore the RLA series in action, showcasing our high-speed robotic lid applicators and precision vision-guided systems.

What are the key benefits of using a lid applicator?

Implementing an advanced lid applicator machine into your production line offers several transformative advantages for manufacturers:

Significant Labor Savings: By replacing repetitive manual tasks with high-speed automation, it drastically reduces labor costs and eliminates human fatigue.

Precision and Consistency: Automated systems provide a level of accuracy unachievable by hand, ensuring a capping and labeling accuracy of ±1mm for a premium product finish.

Increased Production Throughput: Designed for high-volume environments, these machines can handle up to 120 packs/min, significantly boosting the overall efficiency of your wet wipe packaging machine line.

Waste Reduction: The integrated robotic vision system ensures precise glue application and lid positioning, which minimizes material waste and rejected products.

Enhanced Hygiene: The fully automatic process reduces direct human contact with the product, which is critical in the personal care and medical wet wipe packaging machine sectors.

How does the vision system improve the quality of wet wipe packaging?

The vision system performs on-line identification and monitoring of the label position. By measuring the exact angle and coordinates of each pack, it guides the robotic arm to attach the lid with sub-millimeter accuracy. This eliminates misalignment issues commonly found in manual or lower-end automated systems.

How accurate is the lid placement and labeling?

Both models in the RLA series feature high-precision robotic control, achieving a capping accuracy of ±1mm and a labeling accuracy of ±1mm. This level of precision is maintained across various wet wipe packaging machine speeds.

What sizes of lids and wet wipe packs can the machine handle?

The machine is highly adaptable, supporting wet wipe heights from 20mm to 110mm. It can apply caps up to 130mm x 90mm and labels up to 100mm x 80mm, covering the vast majority of consumer and industrial wet wipe formats.

Does the machine require manual intervention for label changes?

Minimal intervention is required. The RLA series is equipped with 2 labeling machines featuring automatic switching functionality. This ensures that your lid applicator machine production line remains uninterrupted when one label roll is exhausted.

Have questions about our wet wipes production equipment, services, or solutions? Reach out to our team—we’re ready to assist you promptly.