In our experience at ZLINK, safety is a cornerstone of any production line. When it comes to automatic lid applicator systems, manufacturers must comply with strict industrial safety standards to protect operators and maintain production integrity. These standards often include electrical safety regulations, mechanical safeguards, emergency stop functions, and proper guarding around moving parts. Our ZLINK RLA Series – Robotic Vision Lid Applicator for Wet Wipes integrates these features, ensuring that the robotic arm operates within a secure environment. By adhering to recognized standards such as CE and ISO certifications, we provide our clients with equipment that meets both domestic and international safety requirements while ensuring consistent operation.

Mechanical and Operational Safeguards

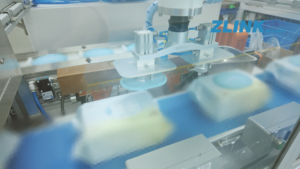

One key aspect of safety for any lid applicator machine is the implementation of mechanical and operational safeguards. At ZLINK, we design our automatic systems to include protective covers, interlocks, and sensors that halt operation if any abnormal activity is detected. The automatic lid applicator utilizes a robotic arm with machine vision technology that accurately monitors the position, angle, and alignment of lids in real time. This not only increases production efficiency but also minimizes risks associated with human intervention. Furthermore, we ensure that all components are tested under rigorous conditions to meet durability and safety benchmarks, providing clients with machines that can reliably operate for years.

Integration of Robotic Vision Technology for Enhanced Safety

Our ZLINK RLA Series combines industrial robotic technology with advanced machine vision to enhance safety throughout the lid attachment process. The vision system detects the exact placement of lids and labels, allowing the robotic arm to perform lid picking, gluing, and attaching without manual assistance. This automated approach reduces human exposure to repetitive tasks, significantly lowering the risk of workplace injuries. By carefully controlling speed, force, and trajectory, the automatic lid applicator ensures that each lid is securely affixed while maintaining consistent safety protocols. Our approach demonstrates that modern automation can effectively balance productivity and operator protection.

Conclusion: Prioritizing Compliance and Efficiency

In conclusion, the safety of automatic lid applicator systems must be considered in multiple dimensions, including mechanical design, electrical compliance, and operational protocols. At ZLINK, we integrate these safety principles into the RLA Series – Robotic Vision Lid Applicator, ensuring that every wet wipe production line operates efficiently and securely. Compliance with CE and ISO standards, combined with our advanced robotic vision technology, allows us to deliver equipment that safeguards both workers and products. By understanding and implementing these safety standards, we help our clients maintain high-quality production while reducing operational risks.