At ZLINK, we understand the critical role a reliable lid plays in maintaining the freshness, hygiene, and overall quality of wet wipes. Traditional manual lid application can introduce inconsistencies that compromise seal integrity, including misaligned lids, uneven glue distribution, or incomplete sealing. By implementing our lid applicator machine, we can achieve precise, repeatable application, ensuring each package is securely sealed and fully protected from contamination. Automation allows us to maintain consistency even during high-volume production runs, while also minimizing human errors that can occur with repetitive manual work. For wet wipe manufacturers, using our system means their products meet higher standards and customers experience a consistent and reliable product every time.

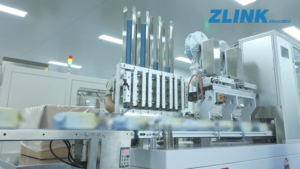

Advanced Robotic Vision Technology

Our ZLINK RLA Series – Robotic Vision Lid Applicator for Wet Wipes combines industrial robotic technology with advanced machine vision, creating a seamless and precise application process. The robotic arm is designed to perform high-speed picking and placing of lids, while the vision system continuously monitors the shape, size, pattern, and relative position of wet wipe packages. This allows the machine to apply glue accurately based on the shape of the lid, ensuring optimal seal integrity. The system can detect slight variations in packaging in real-time and make necessary adjustments, which would be challenging for human operators. By integrating this technology into a wet wipe packaging machine, we significantly improve production accuracy, reduce waste, and maintain consistent hygiene standards, all while maintaining high operational speed.

Efficiency and Productivity Improvements

Incorporating an automated lid applicator machine within a wet wipe packaging machine has a significant impact on efficiency and productivity. Manual lid application is time-consuming and labor-intensive, often leading to slow production cycles or errors during peak output periods. Our automated solution addresses these issues by allowing continuous, high-speed operation without sacrificing precision. The system is flexible, capable of handling different lid shapes and package sizes, making it suitable for a variety of wet wipe lines. Additionally, reducing manual labor decreases operator fatigue and ensures a safer work environment. For companies serving both domestic and international markets, this translates into faster delivery times, reliable product quality, and stronger compliance with hygiene and packaging standards.

Conclusion: Maximizing Seal Integrity

In conclusion, a ZLINK lid applicator machine is an essential tool for maintaining high seal integrity in wet wipe production. The ZLINK RLA Series demonstrates how the combination of robotics and machine vision can achieve precise, consistent, and reliable lid application. By reducing manual errors, improving efficiency, and maintaining stringent quality standards, we provide wet wipe manufacturers with the confidence that every package is properly sealed and ready for the market. Integrating such automated solutions into production lines ensures operational consistency, enhances product safety, and supports long-term reliability, making it a smart choice for companies seeking both efficiency and quality.