In wet wipe manufacturing, the viscosity of the liquid used can significantly impact the production process. Whether you are using an emulsion-like solution or a more liquid formulation, the machinery must be adaptable enough to handle varying viscosities without compromising on the quality or efficiency of the production line. At ZLINK, we understand these challenges as a China wet wipe production line company, and our wet wipe machinery is designed to tackle them head-on, providing smooth, consistent results regardless of liquid consistency.

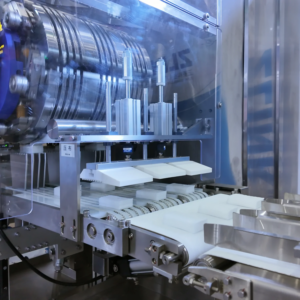

ZLINK’s WE-SF2 Supermini 3D Packing Wipes Production Line: Precision in Liquid Handling

ZLINK’s WE-SF2 Supermini 3D Packing Wipes Production Line is specifically engineered to address the complexities of different liquid viscosities. This advanced machinery offers several features that ensure smooth operation and maintain product quality, no matter the liquid’s thickness.

- Liquid Level Control System

One of the standout features of ZLINK’s wet wipe machinery is its electronic liquid level control system. This system ensures the liquid is applied consistently throughout the production process, even with varying viscosities. The liquid level is automatically monitored and adjusted, preventing any disruptions in the manufacturing process. Whether the liquid is thicker or thinner, this system ensures the right amount is dispensed at all times, preventing waste and ensuring uniform saturation.

- Tension Control and Automatic Web Guider

ZLINK’s machines also feature an independent automatic tension control system. This system detects and adjusts the tension for different liquid viscosities, ensuring that the nonwoven fabric is properly saturated without overloading or under-saturating certain sections. Paired with the automatic web guider, which maintains precise alignment of the nonwoven material, this ensures that production is stable and efficient, regardless of the liquid viscosity.

- Self-Adapting Debugging System

The WE-SF2 Supermini comes equipped with a self-adapting debug system that helps the machine adjust automatically when encountering issues such as inconsistent liquid flow. This is especially crucial when switching between different liquid formulas, as the system continuously fine-tunes the machinery to optimize performance. If a viscosity-related issue arises, the system resolves it on the fly, preventing downtime and ensuring a smooth production process.

Why ZLINK is the Right Choice for Handling Varying Liquid Viscosities

When it comes to wet wipe production, consistency is key, and liquid viscosity plays a critical role in achieving that consistency. ZLINK’s wet wipe machinery, particularly the WE-SF2 Supermini 3D Packing Wipes Production Line, is designed with advanced features that ensure optimal performance with any liquid formula. Our machinery provides precise liquid control, efficient operation, and the flexibility needed to handle varying viscosities—making it the ideal choice for manufacturers who demand the best in quality and efficiency. If you’re ready to take your wet wipe production to the next level, we are here to provide the advanced machinery you need to succeed.