In today’s competitive market, automation has become crucial to maintaining efficiency and quality in production lines. The demand for faster production times, higher consistency, and reduced labor costs makes automation a must-have for businesses in the wet wipes industry. At ZLINK, we provide advanced China baby wipe production line solutions designed to meet the growing demand for seamless integration with robotic systems, specifically robotic cartoning. By integrating automation into every step of the production process, ZLINK ensures that your business stays ahead of the curve, both in production speed and cost efficiency.

How ZLINK’s High-Speed Baby Wipe Production Line Supports Robotic Integration

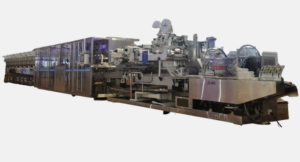

The ZLINK WT-IF Series high-speed multi-lane production line is built with automation at its core. With various configurations, ranging from 20 to 60 lanes, this fully automatic turnkey solution is designed to handle high-volume production of baby wipes without compromising quality. One of the standout features of this production line is its compatibility with robotic cartoning systems.

ZLINK’s production line integrates seamlessly with these systems, enabling smooth transition from wipe production to packaging. Thanks to advanced motion control and multi-axis servo systems, ZLINK’s China baby wipe production line offers precise control over the entire process, allowing robotic arms to quickly and efficiently handle the packaging phase. This means fewer manual interventions, reducing human error and operational costs. With ZLINK’s baby wipe production line promotions, businesses can upgrade to this advanced system at a highly competitive price, making automation more accessible than ever.

Advantages of Integrating a Robotic Cartoning System with Your ZLINK Production Line

Integrating a robotic cartoning system with ZLINK’s baby wipe production line brings numerous benefits that improve both operational efficiency and product consistency. Here are just a few advantages:

– Increased Speed and Precision: Robotic cartoning systems can pack wipes much faster than manual processes, reducing packaging time and improving production output. The integration with ZLINK’s production line ensures that the pace of packaging matches the high-speed wipe production, resulting in fewer bottlenecks.

– Reduced Errors: With robotic systems, the chances of packaging mistakes are minimized. Robots handle the packaging with high precision, ensuring that each wipe is correctly folded and packaged, which is crucial for maintaining quality control standards.

– Cost Savings: Automating the packaging process leads to significant labor savings. By reducing the need for manual labor in the packing stage, businesses can reallocate resources to other areas, maximizing overall productivity. Plus, ZLINK’s baby wipe production line promotions offer a cost-effective solution to upgrade to robotic integration.

Future-Proof Your Production with ZLINK

Investing in ZLINK’s China baby wipe production line and integrating a robotic cartoning system ensures that your business is ready for the future. With faster production, higher-quality wipes, and significant cost savings, this automation upgrade is an essential step in staying competitive. Take advantage of ZLINK’s baby wipe production line promotions today and elevate your business with the latest in production technology. With us, automation is just the beginning.